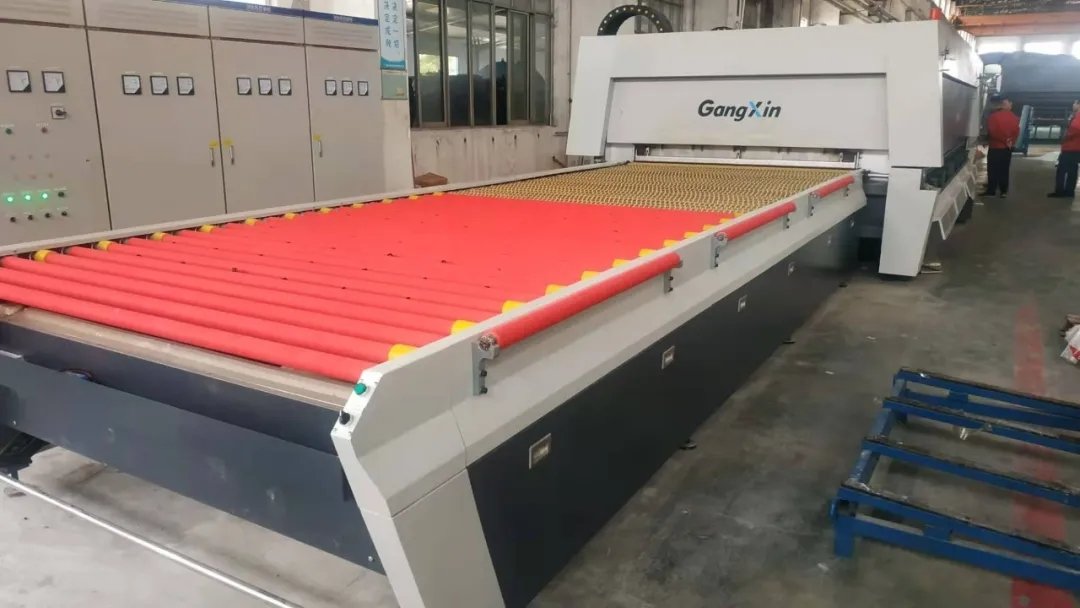

Gangxin high-stress energy-saving fireproof tempering furnace

The fireproof furnace is a kind of tempering furnace. The appearance is not much different from the general tempering furnace. The heating temperature control is more precise, and the blowing air pressure is more uniform and strong, ensuring high-stress tempered glass with high-quality fire-resistant characteristics.

Structure and control system characteristics

1. The whole machine adopts industrial control machine and PLC control, and the main drive adopts imported control system. Frequency conversion stepless speed regulation, high precision and good stability. High degree of automation and simple operation.

2. Lay a layer of magnetized high aluminum plate on the top of the heating chamber to ensure that no impurities will fall off and cause pitting and defects of the product.

3. The heating method adopts the spiral matrix structure, and the furnace temperature is controlled in different areas; the heating elements are finely divided, the design is reasonable, the structure is unique, and the service life is long. The temperature measurement adopts the distributed remote thermocouple temperature measurement module I-7018, which has strong anti-interference ability and high temperature measurement accuracy; the on and off of the furnace wire is controlled by solid-state relays, which has stable and reliable performance and no noise.

4. Fully enclosed heating furnace body adopts high-quality thermal insulation materials with good thermal insulation performance. The heating time from 25℃-700℃ is 3-4h, and the average temperature is lower than 15℃ per hour for 24 hours, and the production energy consumption is low.

5. The heating furnace is divided into upper and lower parts, and the upper part can be raised and lowered freely, which is convenient for maintenance. The heating section drive roller adopts high-quality ceramic rollers with good surface finish and long service life.

6. Full-featured software configuration and reasonable hardware configuration provide great convenience for production, maintenance and adjustment.

7. The fan is an integral rack type.

8. The temperature control algorithm adopts module adjustment, the anti-interference ability is greatly enhanced, the temperature control accuracy is improved, and the performance is more stable and reliable;

9. Three-phase balanced electricity consumption during automatic heating and automatic elimination of phase imbalance during non-heating;

10. The working condition of thermocouple is automatically monitored, and the working condition of the thermocouple is automatically monitored during the production process. If any abnormal working condition of the thermocouple is found, it will automatically alarm and prompt which thermocouple is faulty;

11. The temperature fine-tuning control of the furnace can be realized by adjusting the fine-tuning temperature of each heating electric wire on the upper and lower parts of the furnace. Each furnace wire can be individually set temperature and power. Facilitate the operation of various types of glass.

12 Perfect operation prompt function, for operation and failure in various situations, you can use dialog box to prompt;

13. Misoperation prevention function strictly restricts the value range of the data that affects the normal operation of the system;

14. Automatic storage of alarm records;

15. Strict security measures, different operators have different access rights to system data;

16. Complete monitoring function, the monitoring program can automatically monitor the working conditions of almost all sensors and actuators;

17. The control system can automatically store and update the glass processing parameters;

18. Double belt drive in heating section.

Blowing system

1. The arrangement of air knives and air holes is precise and reasonable;

2. The fan adopts high wind pressure and large flow;

3. Pass-through blower design is more energy-efficient.

Feature heating

1. Increase the number of heating zones to ensure more uniform heating of the glass surface and reduce the rate of self-explosion;

2. High temperature control accuracy;

3. The power of furnace wire is increased, and high-quality nickel-chromium wire is used;

4. The thickness of the furnace body insulation cotton is thickened and nano insulation materials are used.