The degree of tempering is one of the important indicators for measuring the performance of tempered glass. The higher the degree of tempering, the greater the internal stress, the greater the impact strength of the glass, and the smaller the particle size after crushing. The degree of tempering is a function of the heating temperature before glass cooling, which is directly proportional to the heating temperature of the glass. Within a certain range, the higher the heating temperature, the higher the degree of tempering; In terms of thermodynamics, the degree of tempering is actually characterized by the temperature gradient distributed along the thickness direction of the glass; In terms of mechanics, the degree of tempering is represented by the distribution characteristics of internal stress; The degree of tempering can be understood as "the difference in optical path within 1cm"; When other conditions are the same, the degree of toughening is directly proportional to the cooling strength of the glass. The higher the cooling strength, the higher the degree of toughening of the glass.

1. Tempering temperature and degree of tempering

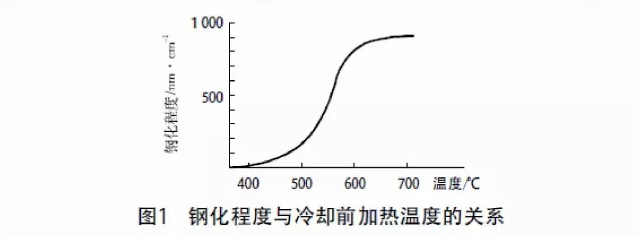

The degree of tempering is a function of the heating temperature before and after glass cooling. When a certain thickness of glass is tempered, the magnitude of internal stress generated by the glass increases with the increase of tempering temperature and cooling strength. When the tempering temperature reaches a certain value, the degree of stress relaxation almost no longer increases, and the internal stress tends to a limit value, which is called the degree of tempering. It depends on the cooling strength, thickness, and chemical composition of the glass. Under the same cooling conditions, the higher the heating temperature, the higher the degree of tempering. But when the heating temperature exceeds a certain range, the degree of tempering remains unchanged, as shown in Figure 1

The heating temperature before cooling tempered glass should be controlled between the glass softening temperature T and the annealing temperature (20~30 ℃ lower than the softening temperature T), and infinitely close to the softening temperature without causing deformation of the glass. That is to say, tempering should be carried out at the highest possible temperature, and the deformation of glass is the highest limit of this temperature.

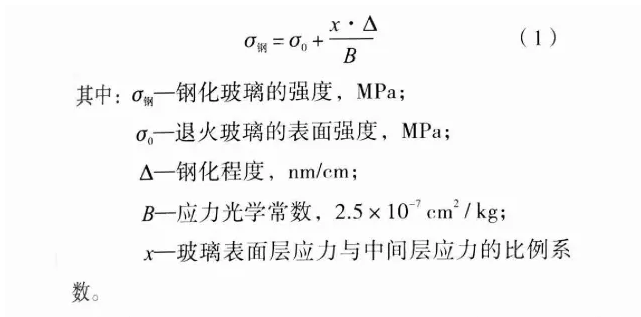

The temperature at which the glass begins to cool evenly during tempering is called the tempering temperature. There is a relationship between the strength of the tempering temperature and the degree of tempering as follows:

From the above formula, it can be seen that the strength of tempered glass increases with the increase of tempering degree and proportion coefficient X. The research results indicate that the strength of tempered glass is mainly determined by the compressive stress (mechanical factor) of the indicator layer, and the changes in the surface layer structure of the glass caused by high-temperature rapid cooling (structural factor) are also important factors affecting physical tempering.

2. Cooling intensity and degree of tempering

The cooling intensity is the main factor affecting the degree of tempering. When glass with the same chemical composition and thickness is heated under the same conditions, its degree of tempering depends on the cooling strength. The higher the cooling intensity, the higher the degree of tempering; For air-cooled tempering, the cooling rate is determined by factors such as wind pressure, air volume, wind temperature, nozzle to glass spacing, and the formation of a hot air cushion. Therefore, the degree of toughening of glass increases with the increase of wind pressure, the increase of air volume, and the decrease of wind temperature. The cooling rate is directly proportional to the wind speed of the cooling air. When the wind pressure and air volume are constant, the smaller the distance between the air nozzle and the glass, the greater the wind speed, and thus the higher the degree of tempering.

3. Tempered particles and degree of tempering

There is a certain relationship between the particle size of tempered glass after crushing and the degree of tempering, and the particle size decreases with the increase of tempering degree. The standard for tempered glass in China requires that the surface stress of tempered glass be greater than 90MPa, and the surface stress of reinforced glass be between 24-69MPa. When the surface stress is 24-69MPa, particles cannot be formed after tempering and crushing. When the surface stress is 95MPa, 50mm × The number of fragments within a 50mm area can reach 40, and when the surface stress is 110MPa, it can reach 60-70 fragments.

The higher the degree of tempering, the greater the stress in the glass. The magnitude and uniformity of internal stress distribution in glass are important characteristics of the degree of toughening. So on a macro level, the size and uniformity of broken tempered glass particles are used to characterize, inspect, and assess the degree of glass tempering and the uniformity of stress distribution in the glass. In production, the size of particles is one of the main indicators for testing the quality of tempered glass. In China's tempered glass standard GB 15763.2-2005, a requirement of 50mm is required × The number of 3mm glass particles within a 50mm area is 30, while in the European standard EN12150, there are 15 particles. The same regulations apply to 4-12mm glass, both of which are 40 particles.

4. Glass thickness and degree of toughening

Due to the fact that the generation of internal stress in glass depends on the presence of temperature gradients in the glass, the thicker the glass, the greater the temperature gradient during quenching. When the conditions are the same, the thicker the glass, the higher the degree of toughening.

When the thickness of the glass decreases by 10%, the degree of toughening decreases by 6%, and a 7% increase in heat exchange efficiency is needed to compensate. In actual production, it is often achieved by increasing the quenching air pressure of the air grille. Tempered thin glass often lowers the temperature of the cooling medium to improve its heat exchange efficiency with glass. When the production conditions are the same, after tempering treatment, the tempering degree of 6mm thick glass is higher than that of 5mm thick glass. If you want them to have the same degree of toughening, you must increase the cooling intensity of the latter. Otherwise, if the cooling intensity is the same, the toughening degree of 5mm thick tempered glass will be lower than the former, manifested as the broken debris particles being larger than 6mm.

5 Conclusion

The principle of physical toughening is to evenly heat the glass to a suitable temperature and keep it warm for a certain period of time, in order to achieve uniform temperature throughout the interior. After the stress is completely relaxed, it quickly cools down, causing the surface of the glass to contract sharply and generate compressive stress. However, the cooling of the middle layer of the glass is slow and there is not enough time to shrink, resulting in tensile stress, which enables the glass to achieve higher strength. Generally speaking, the higher the cooling intensity, the greater the strength of the glass. However, if the cooling intensity is too high, it will exceed the limit due to excessive stress, breaking the stress balance and making tempered glass more prone to cracking. Therefore, special care must be taken when toughening glass, carefully adjusting temperature, time, cooling speed, air volume, air pressure, etc. to achieve the best toughening effect.

The above content is excerpted from building glass and industrial glass WeChat official account

Slightly deleted, please indicate the source if cited.