Service Hotline

Service Hotline

TEL:+86-18637917090Email:export01@lygangxinglass.com

Service Hotline

TEL:+86-18637917090

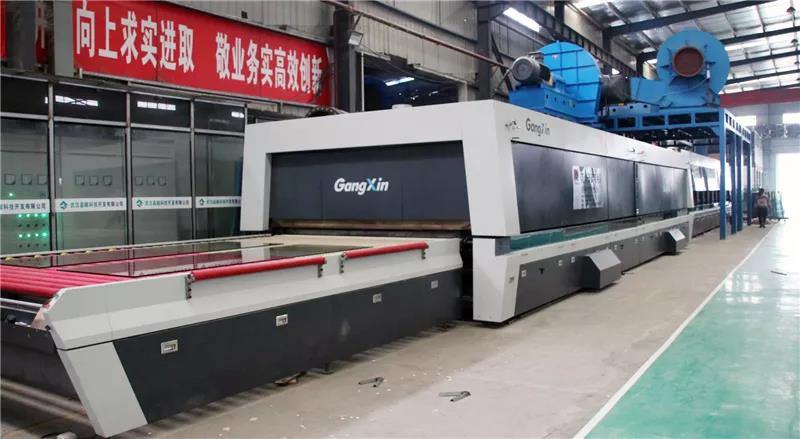

The fourth generation of high stress and high boron silicon 4.0 double room fire resistant tempering furnace

It can toughen 5mm, 6mm high stress fireproof glass and high borosilicate 4.0 fireproof glass, and can process the maximum specification of 2.44m × 4.2m, the longest fire resistance time is more than 180 minutes, the new heating chamber design, upgrade constant temperature convection mode, ensure that the glass imaging is good, the stress spot is light, the stress is uniform, the self explosion rate is low, the particle size is more than 40.

Equipment composition and manufacturing standards

The lamp tube is installed at the upper and lower ends for the convenience of the customer to check the glass defects, and the installation of safety socket will bring greater convenience to the customer to repair the glass. The storage bucket is convenient for placing any goods conducive to production

The section includes a combined steel frame, a transmission system, a landing gear, a photoelectric switch, etc

The drive motor of the upper plate is driven by frequency converter, and the placed glass is transmitted to the photoelectric switch of front furnace door of heating furnace, and the furnace is ready for entering. During the furnace entering, the frequency converter drives the motor to drive the roller table to run at high speed and transport the glass to the heater for heating. The length of glass is accurately measured and recorded by photoelectric switch and furnace encoder. The distance of glass loading can be changed by human-computer interface according to the size of glass. The universal ball table mechanism with pneumatic device can control the lifting and lowering manually, which is more suitable for the large glass mounting.

The heating furnace is a steel structure with upper and lower sections. The upper furnace body can rise and fall freely through the furnace top lifting mechanism. The lifting height is 450mm, which is convenient for maintenance and cleaning. High density ceramic fibreboard is used as thermal insulation material of furnace body, and the surface is treated with high temperature resistant adhesive. A layer of magnetized high aluminum plate is laid inside the furnace to ensure that no impurities will fall, causing pockmarks and defects of products. Each convection fan adopts frequency conversion control, which can be controlled separately. According to the heating principle of glass, automatically adjust the wind pressure. The convection fan is arranged in the middle of the furnace top, and the double air outlet design is adopted to make the air pressure more uniform. The motor bearing adopts air cooling to extend the bearing life.

Double belt drive, better synchronization, higher safety performance.

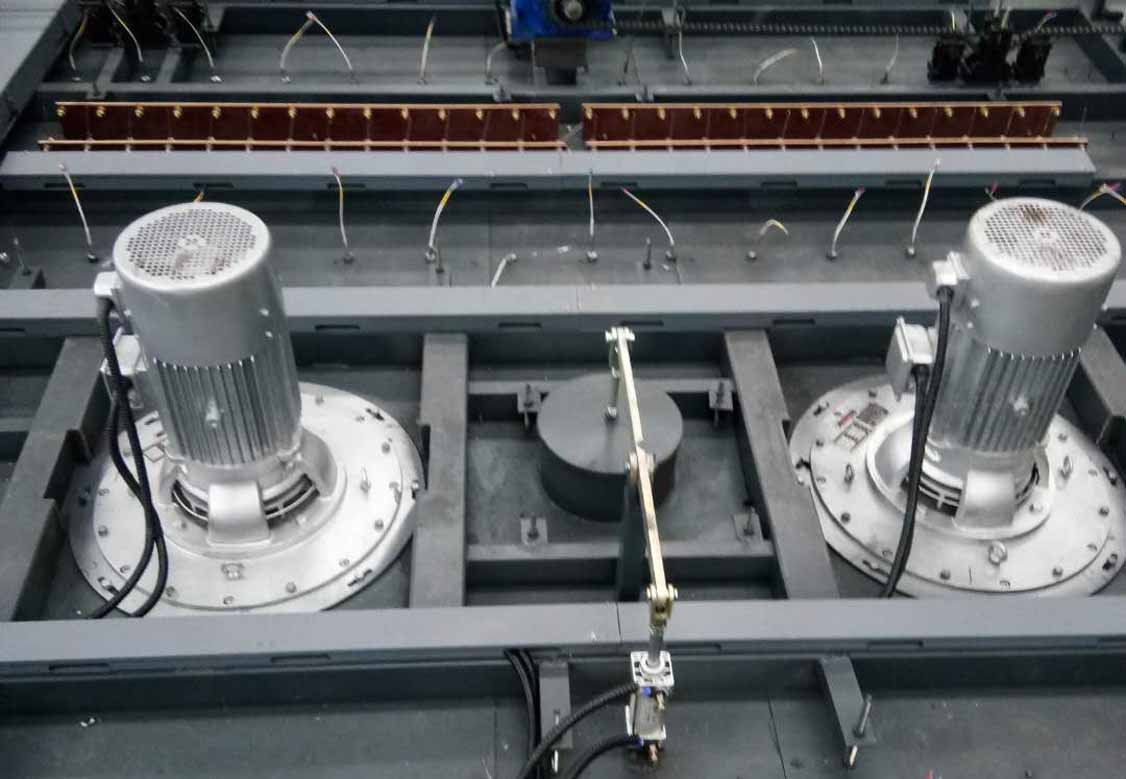

Upper internal circulation convection fan

Each convection fan adopts frequency conversion control, which can be controlled separately. According to the heating principle of glass, automatically adjust the wind pressure. The convection fan is arranged in the middle of the furnace top, and the double air outlet design is adopted to make the air pressure more uniform. The motor bearing adopts air cooling to extend the bearing life.

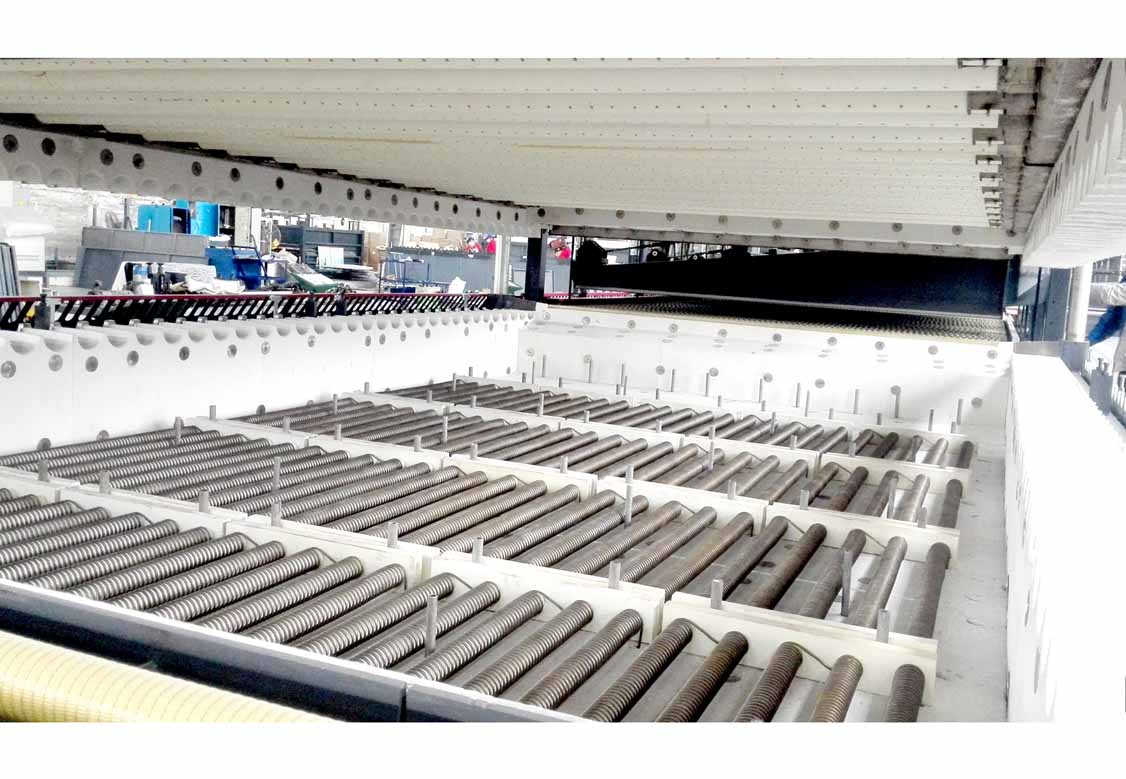

Internal stainless steel convection system

The forced convection system added in the furnace body is composed of convection fan, air inlet pipe, air outlet pipe, etc

The upper ceramic pipe is used to prevent the deformation and slag falling in the furnace at high temperature. And absolutely insulated.

According to the size of the furnace body, there are different arrangements. It has the characteristics of simple structure, easy installation and long service life. The installation mode adopts suspension installation mode, which is convenient for installation and maintenance. The installation of each furnace wire is independent, and the removal and replacement of faulty furnace wire will never damage other furnace wires. The furnace wire has a single point control function. Each furnace wire has a separate thermocouple for temperature measurement, and can set the temperature and power separately to make the temperature in the furnace as uniform as possible.

The lower radiant plate is corrugated to increase the strength of the radiant plate, without deformation at high temperature

The roller hole is made of customized insulating bricks with accurate diameter, small gap, durable, heat preservation and easy replacement.

The outer sealing ring is designed so that the temperature inside the furnace will not emit heat through the gap between roller joints

The high quality ceramic roller is used for furnace body transmission, with high surface finish and long life. The ceramic roller is driven by circular belt, and the frequency conversion speed control ensures the synchronization and stability of the movement. Equipped with roller conveyor, installation of roller table is convenient and fast.

The transmission shaft of the furnace body adopts the plating shaft, with smooth surface quality and accurate straightness. V-groove is opened between 45 ℃ in the shaft length direction to fix the belt pulley. The belt pulley is easy to install and firmly fixed. The shaft head adopts the outer square, the coupling adopts the inner square, the connection is more firm, the transmission between the shafts is frameless, so as to avoid the collision of glass in the furnace

The lifting mechanism of the upper and lower air grates can adjust the height of the upper air grates independently, which makes it more convenient to adjust the flatness of the glass. The small air box is formed by bending a cold plate at one time. The air outlet is made of aluminum alloy cold drawn on a single air box and sealed with glue. The roller table is made of high-quality cold drawn steel rolls with thick wall. The rope winding part of each steel roll is slotted for glue treatment. The high temperature resistant rope is closely bonded with the steel roll by high temperature glue and is baked for heat treatment. Chain drive, better synchronization.

The small bellows can be cleaned, and each small bellows has separate baffle at both ends, which can be disassembled separately. It is convenient and fast to clean the internal stolen goods

The fan is of integral frame type. Anti vibration cushion support. On site installation saves time, labor and place

Line configuration: CE standard is used for all electrical parts and wiring in the cabinet. The power cable (including the cable connecting inverter and fan) required by the equipment shall be provided by Party A.

PLC uses the products of OMRON company in Japan.

The program has reliable stability and friendly man-machine interface, many abnormal alarm functions (including encoder connector loose, parameter setting error) and alarm log, for maintenance personnel to refer to and view

The temperature control adopts module adjustment, which greatly enhances the anti-interference ability, improves the temperature control accuracy, and makes the performance more stable and reliable; The modular heating system can set heating curve according to different glass layout, and each heating element can set temperature and adjust power independently.

The module is a small computer, which connects the temperature signal collected by the temperature acquisition module to the control module, and then controls the on-off of the furnace wire according to the control requirements (the control requirements include the temperature setting value and power setting value), and the control accuracy is within 3 degrees. The upper computer is industrial control computer.

The operation platform adopts independent cantilever type, does not occupy space. It can rotate in all directions, and can better prevent interference

Structure and control system characteristics

1 、The whole machine adopts industrial control machine and PLC control, and the main drive adopts imported control system. Variable frequency stepless speed regulation, high precision and good stability. High degree of automation, simple operation.

2 、A layer of magnetized high aluminum plate is laid on the top of the heating chamber to ensure that no impurities will fall, causing pockmarks and defects.

3、The heating mode adopts spiral matrix structure, and the furnace temperature is controlled by regions; The heating element has fine zoning, reasonable design, unique structure and long service life. The distributed remote thermocouple temperature measurement module i-7018 is used for temperature measurement, which has strong anti-interference ability and high temperature measurement accuracy; The furnace wire is controlled by solid state relay, with stable and reliable performance and no noise.

4 、The fully enclosed heating furnace body is made of high-quality thermal insulation materials with good thermal insulation performance. The heating time from 25 ℃ to 700 ℃ is 3-4h, the natural cooling time is 24 hours, and the average temperature per hour is less than 15 ℃. The production energy consumption is low.

5 、The heating furnace is divided into upper and lower parts. The upper part can rise and fall freely, which is convenient for maintenance. High quality ceramic rollers are used in the driving roller table of heating section, with good surface finish and long service life.

6 、Full function software configuration and reasonable hardware configuration provide great convenience for production, maintenance and adjustment.

7 、 The fan is of integral frame type.

8 、The temperature control algorithm adopts module adjustment, which greatly enhances the anti-interference ability, improves the temperature control accuracy, and makes the performance more stable and reliable;

9 、The three-phase equilibrium power consumption in automatic heating and the phase imbalance in non heating process are automatically eliminated;

10 、 Automatic monitoring of thermocouple working condition, automatic monitoring of thermocouple working condition in the production process, if it is found that there is abnormal thermocouple working, it will automatically alarm and prompt which thermocouple has problems;

11 、The temperature fine-tuning control of the furnace can be realized by adjusting the fine-tuning temperature of each heating wire at the upper and lower parts of the furnace. The temperature and power of each wire can be set separately. It is convenient to operate all kinds of glass.

12 、 Perfect operation prompt function, for all kinds of operation and fault conditions, you can use the dialog box to prompt;

13 、The misoperation prevention function strictly limits the range of data that affect the normal operation of the system;

14 、Automatic storage of alarm records;

15 、Strict security measures, different operators have different access to system data;

16 、Perfect monitoring function, the monitoring program can automatically monitor almost all the working conditions of sensors and actuators;

17 、The control system can automatically store and update the processing parameters of glass;

18 、Heating section double belt drive.

Technical service:

1. To provide users with equipment, process and technical consultation, put forward the best applicable model, plane layout and equipment installation site basic requirements of the technical scheme, in order to facilitate users to make reference selection.

2. Install, debug and accept the sold equipment as planned, debug the best process parameters according to the technical requirements, and produce qualified tempered glass products.

3. Provide free technical service for lifetime maintenance of equipment.

4. Responsible for the organization and implementation of necessary technical transformation and upgrading after long-term operation of the equipment, so as to make the equipment in the best operation state.

Technical training for user personnel:

1. Provide user's technical guide, including equipment technical description, common troubleshooting, processing method and conventional process parameters.

2. Carry out pre-sales and after-sales theoretical and practical training for user operators to ensure that they can operate independently.

3.Answer and solve the difficult problems in the process of production and maintenance at any time.

After-sale service:

Our company will deliver the goods in time according to the requirements of the contract, and send technicians to the buyer to guide the buyer's technical workers in installation, commissioning and production, and provide technical training for the buyer's operators. During the one-year warranty period, spare parts and technical services damaged due to quality problems shall be provided to the buyer free of charge.

Provide the buyer with relevant technical data of auxiliary materials required in the production process free of charge.

Our company adopts the whole process tracking service, establishes the user service hotline, receives the user's call at any time, wholeheartedly provides the high quality equipment and the good service for the customer, the user's production and the product quality can obtain the effective guarantee. If users have problems that they can't solve, our technicians will go to the site for technical service within 24 hours in mainland China.

For users to create the greatest benefit is the purpose of our company's service!

Whatsapp Scanning

Luoyang GangXin Glass Technology Co.,Ltd

Add: No.246, Jinshui Avenue, Airport Industrial Zone, Luoyang, Henan Province China

Tel: +86-186 3791 7090

Fax: +86-379-62201609

E-Mail: export01@lygangxinglass.com

Oversea Sales Manager: Tracy Liu

Email: export01@lygangxinglass.com

Mob/Whatsapp: +86-186 3791 7090

Oversea Sales: Michael Sun

Email: sales01@lygangxinglass.com

Mob/Whatsapp:+86-186 3848 1875

© 2021-2023 Luoyang GangXin Glass Technology Co.,Ltd all rights reserved 豫ICP备11020387号-1丨营业执照 Technical support: Glacn.cn